ANAND IMPEX

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ANAND IMPEX

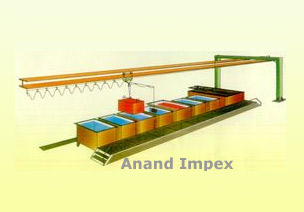

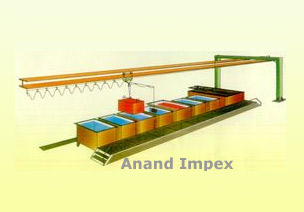

Pretreatment Systems Dip Type Overhead Conveyors

The article are hanged on the Overhead Conveyor which takes vertical up & down bends inside the pretreatment tanks. The tanks are made sloping at entry and exit. Generally the conveyor speed is fixed and tank lengths vary according th chemical specifications (Dipping type).

This system is suitable for small and medium articles having low weights, few chemical requirements.

Pretreatment Systems Dip Type Twin Hoist

The dip phosphating plant consists of a number of tanks arranged sequentially. The article to be phosphated are loaded in suitable cages abd are transported by an overhead hoist from tank to tank manually or automatically. In Twin hoist system two hoists lift the cage.

Pretreatment Systems Dip Type Transporter

For complete automation of handling of cages in pretreatment system transporters are provided.

Semiautomatic version is also available. It has wide load carrying capacity (200 to 1000 kg.) P.L.C. based control are provided for integrated plant management system.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

60993.jpg)

60994.jpg)

60995.jpg)